Ramsey/Washington Recycling & Energy (R&E) is continually expanding its efforts to minimize waste generated in the community, while recovering value from waste that arrives at the R&E Center. Through R&E, the counties are increasing investments in waste reduction, reuse and recycling. Examples include:

With a focus on recovering value from waste and opportunities presented by new technology, the counties’ plans also include upgrading the Recycling & Energy Center:

When Ramsey and Washington counties were considering purchase of the Recycling & Energy Center, they focused on how the facility could best serve as part of an effective solid waste management system well into the future. In doing so, they adopted the following guiding principles for design of the waste and recycling system:

Considerable research and evaluation has shaped the development of the R&E waste management system:

Ramsey/Washington Recycling & Energy has partnered with Dem-Con HZI Bioenergy, LLC to build a regional anaerobic digestion facility to process food scraps and other organic material. This unique public-private partnership offers an environmentally sustainable solution for managing food scraps and other organic waste, while generating carbon-negative renewable energy and combating climate change.

The proposed facility would be located in Louisville Township in Scott County and is designed to process up to 75,000 tons of organic waste each year. About 50,000 tons would come from Ramsey and Washington counties through the Food Scraps Pickup Program and organic materials recovered at the R&E Center.

Dem-Con HZI Bioenergy formed between two companies to build and operate this new facility. Dem-Con Companies is a third-generation family business, with decades of expertise in managing waste and recycling facilities in Minnesota. They partnered with Kanadevia Inova, formerly known as Hitachi Zosen Inova, a globally renowned anaerobic digestion technology provider with nearly 100 digesters operating in North America and Europe.

This proposed facility would be a vital part of the region’s efforts to reduce waste and combat climate change. Food scraps make up more than 20% of residential trash in Ramsey and Washington counties, and this facility would keep this material out of landfills and incinerators.

When food scraps end up in landfills, they generate a large amount of greenhouse gases – primarily methane – that enter the atmosphere. According to the Environmental Protection Agency, about 58% of methane emissions from municipal landfills come from food scraps. Methane is considered one of the worst climate pollutants because it traps a large amount of heat in the atmosphere. When food scraps and other organic materials are managed at waste-to-energy facilities, they require more energy to incinerate than other waste because they are wet.

We need many tools to manage the large amount of food scraps in our waste stream. Anaerobic digestion would provide a large-scale solution that would complement other tools like food rescue, food waste prevention, local compost facilities and backyard composting.

Anaerobic digestion is relatively new in the United States, but it’s been used in Europe for decades. Digestion is a proven, effective solution to reduce greenhouse gas emissions while creating valuable, renewable products from waste.

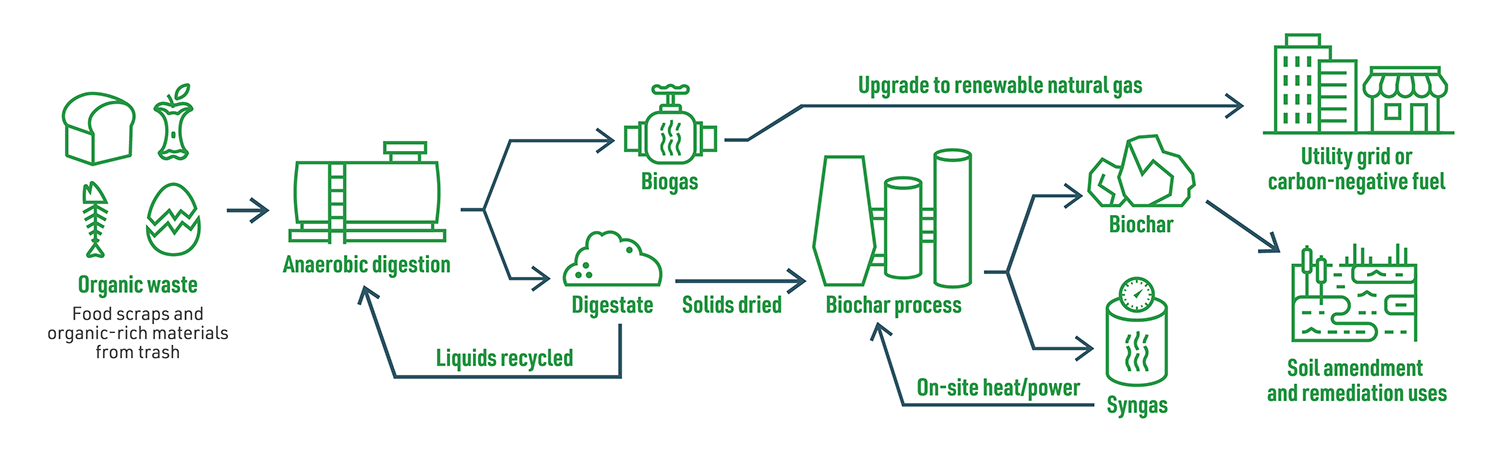

Food scraps and other organic materials would be transported from the R&E Center in Newport to the proposed digester facility in Scott County. Materials would be placed in the digestion unit, a large, airtight tank without oxygen where microbes break down the food scraps and organic materials.

The process is like a backyard compost bin, but at a commercial scale. Materials are pushed through the digestion unit in one to two weeks. The process will create two products: biogas and digestate. The biogas would go through a biogas upgrader to create renewable natural gas (RNG). The digestate would go through a gasification process to make biochar.

The proposed facility would create two valuable recycled products, both of which eliminate waste and provide solutions to address climate change:

The process of making biochar and use of biochar in remediation have shown promise in reducing per- and polyfluoroalkyl substances (PFAS) – a class of toxic chemicals that are notoriously difficult to manage.

This project would be the first of its kind in the country.

This project is currently going through the local permitting phase with Scott County and Louisville Township. Once permitting is completed, the facility would take two years to construct, after which it would begin producing renewable natural gas and biochar.

Check back for timeline updates as the planning process continues.

This project has received critical financial support from the following: